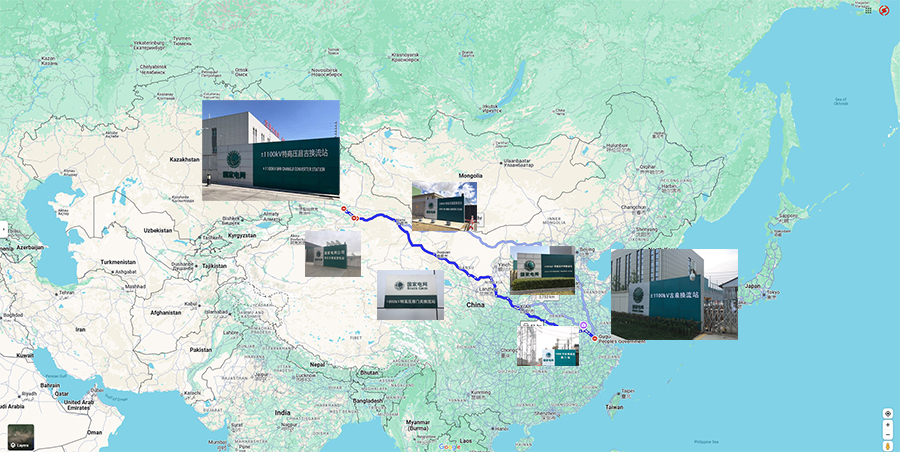

Project: The ±1100 kV UHVDC Changji-Guquan Transmission Project, approved by China’s NDRC on Dec 28, 2015, spans 3,304.7 km from Changji Converter Station (Xinjiang) to Guquan Converter Station (Anhui), traversing 6 provinces/regions (Xinjiang, Gansu, Ningxia, Shaanxi, Henan, Anhui).

Specifications:

Voltage: ±1100 kV DC (world’s highest)

Capacity: 12 GW (12,000 MW)

SH POWER Involvement (End-2024): Constructed this project plus 22 UHVAC (1000 kV) and 23 UHVDC (±800 kV) transmission & transformation projects.

UHV Tech Characteristics:

Ultra-high voltage (±800/±1100 kV DC; 1000 kV AC)

Long-distance (>3000 km), large-capacity (GW-scale)

High technical complexity, cross-regional suitability

Economic efficiency, reduced environmental impact

UHV Hardware Requirements: Designed for extreme electrical/mechanical stress, featuring:

Exceptional insulation & mechanical strength

High-temperature & fatigue resistance

Precision engineering & diverse components

Long service life & environmental compatibility

Key Changes for Conciseness:

Merged Sections: Combined project approval, route, and specs into a single flowing sentence.

Simplified Lists: Used semicolons and parentheses for UHV characteristics and hardware requirements instead of separate bullet points.

Removed Redundancy:

Dropped “Ultra High Voltage Direct Current (UHVDC)” after first use (implied by ±1100 kV).

Removed detailed explanations of benefits (e.g., “Minimizes land usage…”).

Shortened “provincial-level administrative regions” to “provinces/regions” (contextually clear).

Condensed SH POWER’s project list description.

Stronger Verbs: Replaced phrases like “has participated in the construction of” with “Constructed”.

Technical Precision Retained: Kept critical terms: UHVDC/UHVAC, ±1100 kV/1000 kV, GW, converter station, insulation, mechanical strength, fatigue resistance, precision engineering.

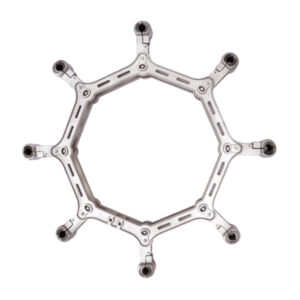

Product Introduction:

|  |  |  |

8 spacer damper(Casting) Suitable for voltage levels of ±1100 kV, conductor cross-sectional area of 1250 mm², splitting spacing of 550 mm, conductor splitting circle diameter of 1437 mm, and short-circuit current not less than 50 kA. | 8 spacer damper(Forging) Suitable for voltage levels of 1000 kV, conductor cross-sectional area of 630 mm², splitting spacing of 400 mm, conductor splitting circle diameter of 1045 mm, and short-circuit current not less than 50 kA. | 6 spacer damper(Forging) Suitable for voltage levels of ±800 kV, conductor cross-sectional area of 1250 mm², splitting spacing of 500 mm, conductor splitting circle diameter of 1000 mm, and short-circuit current not less than 75 kA. | suspension clamp Aluminum alloy forging process, suitable for a maximum conductor diameter of 70 mm, with a clamp grip strength of no less than 25% of the conductor’s rated breaking force, and a maximum clamp strength of 300 kN. |

|  |  |  |

NY suspension clamp Suitable for conductor JL/G2A-1250/100, with a tension clamp grip strength of no less than 313.36 kN. | vibration damper Suitable for a maximum conductor diameter of 48 mm. | ball-eye Nominal breaking load max 550 kN. | socket-clevis Nominal breaking load max 550 kN. |

|  |

| |

shackle Nominal breaking load max 1280kN. | z clevis Nominal breaking load max 2560kN. |