- info@shpowerglobal.com

- +86 0514-8033 0588

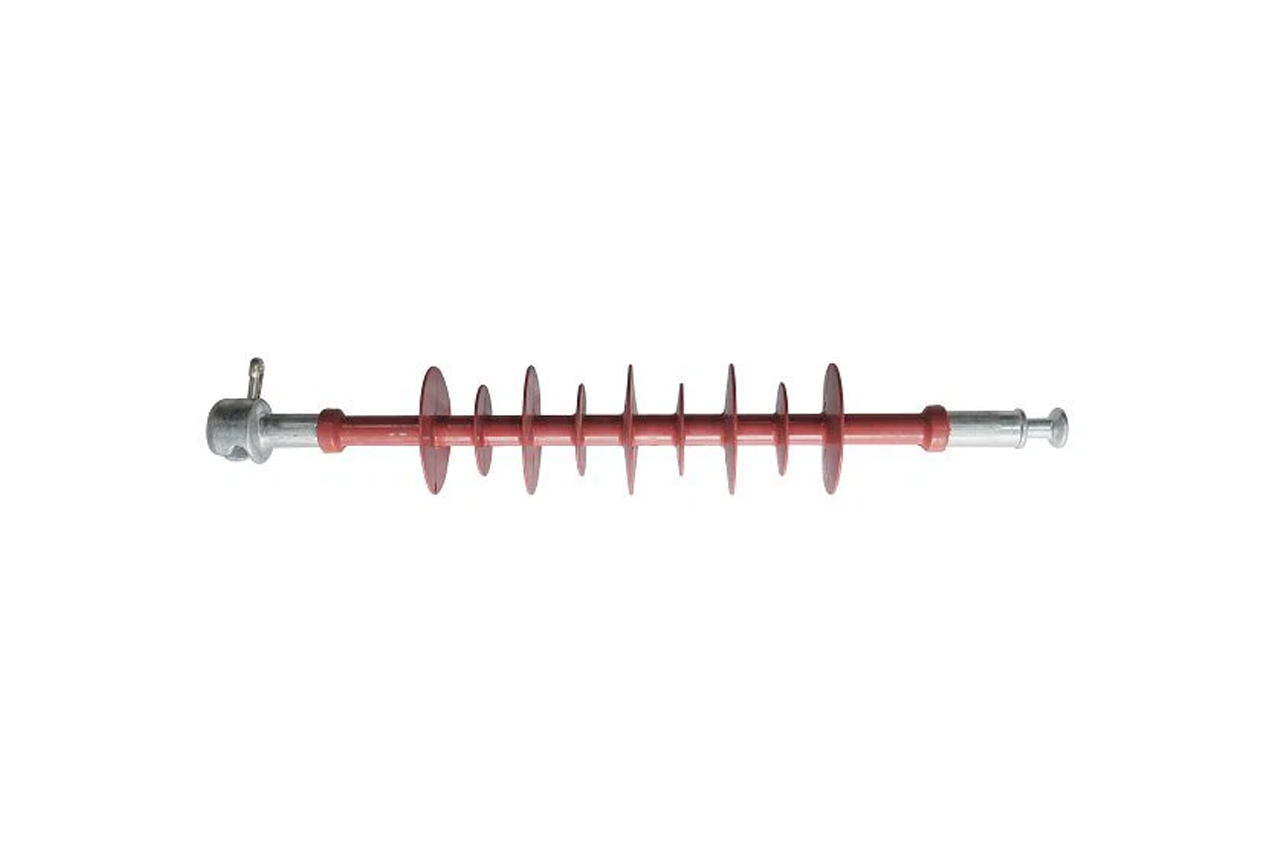

The end of the 35kV composite suspension insulator adopts labyrinth type waterproof design and adopts the outer covering rubber process, which greatly improves the waterproof and impermeable performance of the product.

The 10kV composite suspension insulator consists of glass fiber epoxy core, silicone rubber shed and metal fittings. The silicone rubber shed adopts integrated injection compression technology, which solves the key problem of electrical breakdown at the interface that affects the reliability of the composite insulator.

We use the best raw material , and every single product will go through a series of strict test.

Composite post insulator is suitable for power facilities.It has good hydrophobicity,ageing resistance,tracking resistance and electrical erosion resistance,it also has good performance for bending resistance,torsion resistance and impulse resistance.

Small volume,light weight,sheds have good elasticity,not broken, convenient transportation and installation, economy.

The material of metal end fittings is used with hot galvanization and technology of rare earth aluminum coating to avoid coating shedding when crimping, prolonging the service life of the product.

It's small in size and in light weight, it is about 1/5 to 1/9 of the porcelain insulator in the same grade voltage, so it's convenient for transportation and installation.

Characteristics: Small volume and light weight,easy to transport and install. The superior in performance and high intensity mechanical enhance reliability of power line. Extraordinary hydrophobic and resistance to contamination. Long-duration resistance aging and leakage tracking.

Excellent stain resistance. The pollution flashover voltage is 2-3 times that of porcelain insulators, so this product is especially suitable for dirty areas.