Overview

Recently, our company has successfully won the bid for the supply of aluminum alloy conductor cables (AAAC 570 mm²) power hardware project of the Algerian National Electricity Company (SONELGAZ) with its excellent technical strength and reliable product quality. The project covers 400kV and 220kV high-voltage transmission lines and has won three bid packages.

Technical Strengths and Product Advantages

High-strength corrosion-resistant design

- Utilizing high-strength aluminum alloy combined with hot-dip galvanizing process, it is adapted to the high-temperature, dusty, and coastal high-salt fog environment in Algeria, ensuring maintenance-free operation for 30 years.

- Certified by the IEC 61284 international standard, it meets the mechanical load requirements for 400kV/220kV lines.

Lightweight and low loss

- Optimized structural design reduces the weight by 15% compared with traditional hardware, lowering the tower load and enhancing the economic efficiency of the line.

- Adopting low-corona design to reduce electrical energy loss and ensure the efficiency of high-voltage transmission.

Intelligent adaptability

- Precisely matched with AAAC 570 mm² conductors, it supports extreme temperature working conditions ranging from -40℃ to 80℃.

- Modular design for easy installation, significantly shortening the construction period.

As a key equipment supplier for the project, SH Power provides the following products and services:

| Application Scenario | Product Name & Model | Technical Specifications |

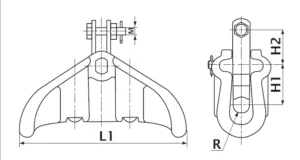

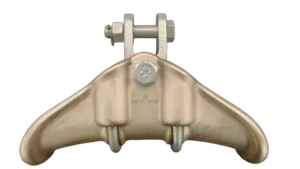

| Gobi Desert Conductor Suspension | Aluminum Alloy Forged Suspension Clamp (XGD-25/70-50) | Nominal breaking load: 250 kN; Grip strength ≥24% of conductor breaking load; Salt spray corrosion resistance life >30 years |

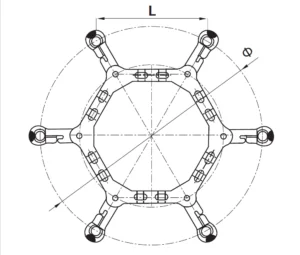

| High-Wind Zone Galloping Control | Six-Bundle Anti-Galloping Spacer (FSD-6X) | Galloping amplitude reduction: 70%; Conductor displacement <1.5 m under Beaufort scale 12 winds (32.7–36.9 m/s) |