Production Capacity

Global Manufacturing Power for Energy Infrastructure

As a trusted energy infrastructure partner, SH POWER delivers advanced manufacturing solutions and reliable global supply for energy infrastructure projects, ranking among the world’s top five in production and processing capability.

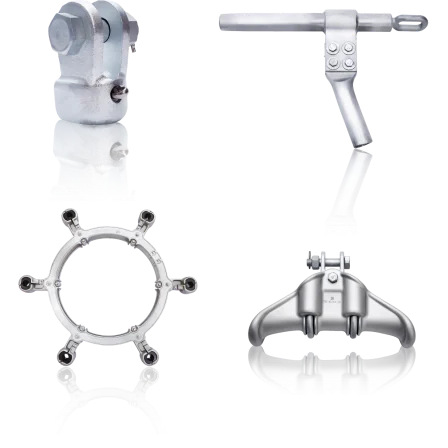

Low-Pressure Die Casting (LPDC)

The LPDC process introduces molten aluminum into the mold in a controlled, upward flow, making it ideal for high-reliability components used in global energy infrastructure. This method fundamentally prevents internal defects such as porosity and shrinkage. It is especially suitable for producing large, complex power fittings like corona rings, ensuring a highly dense internal structure and superior mechanical properties.

Core Advantages:

Superior internal density and mechanical strength.

Perfectly suited for large and complex geometries.

Ensures exceptional product reliability and batch-to-batch consistency.

High-Pressure Die Casting (HPDC)

For high-volume production, HPDC is the optimal solution for maximizing efficiency. This process injects molten aluminum at high speed and pressure, allowing rapid solidification while producing parts with high dimensional accuracy, excellent surface finish, and intricate details for energy infrastructure projects.

Core Advantages:

Efficient mass production for accelerated project delivery.

Outstanding dimensional accuracy and surface finish.

Capable of producing small-to-medium-sized power fittings with complex geometries.

Aluminum Forging

Forging is the definitive process for aluminum components subjected to extreme tension and stress in energy infrastructure applications. By compressing aluminum billets under immense pressure, the metallurgical grain structure is refined and compacted, resulting in vastly superior strength, toughness, and fatigue resistance compared to castings.

Core Advantages:

The pinnacle of mechanical performance, with strength and toughness far exceeding castings.

Enhanced safety margins and an extended operational lifespan.

Proven reliability in the most demanding high-stress environments.

CNC Machining Center

We treat precision as an absolute standard, not just a goal. SH POWER’s CNC machining centers transform complex digital models into physical reality with micron-level accuracy, meticulously executing every cut and drill. This rigorous approach ensures that the final component is a perfect reflection of your engineering design, down to the smallest detail.

Core Advantages: Guarantees seamless on-site assembly and component interoperability.

Eliminates dimensional deviations, ensuring design integrity.

Provides absolute consistency across every unit produced.

Screw Press (300kN – 4000kN)

Our comprehensive suite of screw presses ranges from 300kN to 4000kN, providing exceptional versatility for forging energy infrastructure components. These presses apply precise force to produce everything from small fittings to large structural parts, ensuring optimal mechanical properties.

Core Advantages: Versatility to produce a wide range of component sizes.

Stable forming with excellent mechanical properties.

A one-stop solution for diverse manufacturing requirements.

Triangle Wound Core Coil Winding

Our adoption of triangular wound core technology is a significant leap beyond traditional laminated cores. This innovative structure is engineered to minimize no-load losses, boost energy efficiency, and, combined with our advanced coil winding, creates more stable and durable transformer cores.

Core Advantages: Superior energy efficiency with demonstrably lower operational costs.

Enhanced stability and a longer service lifespan for transformers.

A distinct technological advantage that translates to superior product performance.

CNC Automatic Slitting Line

We utilize a high-precision CNC slitting line that accurately and rapidly slits silicon-steel coils of various specifications. The automated system guarantees consistent slit width, smooth edges and burr-free cuts, laying a solid foundation for low-loss, high-performance core production.

Core Advantages: High efficiency with minimal dimensional tolerance.

Enhances magnetic performance and reduces energy loss.

Ensures consistency and stability across production batches.

Automatic Core Stacking System

Our automatic core-lamination system reads the design file and handles sheet picking, stacking and clamping without human intervention. This boosts throughput and, more importantly, guarantees stacking accuracy and tightness, minimizing air gaps in the magnetic circuit. As a result, no-load losses and no-load current are far lower than those of traditional hand-built cores.

Core Advantages: Automation ensures efficiency far beyond manual stacking.

Superior consistency for stable magnetic performance.

Minimizes human error and enhances overall product quality.

Hot-Air Circulation Vacuum Drying

Equipped with state-of-the-art vacuum-drying plant that combines hot-air circulation with deep-vacuum technology, we remove >99 % of residual moisture from active parts. The thorough, uniform drying raises insulation class and cuts dielectric-loss tangent, providing an indispensable guarantee for high-voltage, large-capacity, long-life transformers.

Core Advantages: Delays insulation aging, ensuring long-term reliability.

Ideal for deep drying of large and thick insulation components.

Improves transformer durability in harsh environments.

Vacuum Oil-Filling Line

Our vacuum oil-filling line injects transformer oil—precisely filtered, degassed and dewatered—while the active part remains under vacuum. This process eliminates any bubble formation and allows the oil to penetrate every corner of the insulation paper, creating a flawless dielectric system that greatly enhances electrical insulation strength and long-term operational reliability.

Core Advantages: Prevents partial discharge and insulation breakdown.

Enhances overall operational safety and reliability.

Extends equipment lifespan and reduces maintenance costs.

Static Mixing & Casting

Our static mixing-and-casting plant is dedicated to high-performance epoxy-resin cast-resin dry-type transformers. It meters the two-component epoxy with precision, blends it to ultimate homogeneity and casts under vacuum, ensuring the windings are fully embedded in a void-free, highly thermally-conductive epoxy solid. The result delivers outstanding moisture resistance, fire resistance, short-circuit withstand and environmental friendliness.

Core Advantages: Ensures uniform and dense insulation without voids.

Greatly enhances moisture resistance and crack resistance.

Extends product lifespan and operational stability.

Transformer Production Line

We operate a fully integrated power transformer production line that links every advanced unit and process described above. The line covers core cutting, coil making, active-part assembly, vacuum drying, final assembly, and routine tests. With standardized, automated, and quality-controlled workflows, we efficiently deliver a full range of high-performance, high-reliability power transformers for energy infrastructure, including both oil-immersed and dry-type models.

Core Advantages: Parallel lines for dry-type and oil-immersed transformers covering the full product range.

High productivity, reducing delivery lead times.

Flexible switch between customized and mass production.

FAQ

SH POWER operates advanced manufacturing lines with strong global production capacity, enabling stable, large-scale output. Every product undergoes strict testing before delivery, guaranteeing reliability and performance.

Yes. Our production lines—including advanced die casting (LPDC/HPDC), forging, CNC machining, and automated workflows—are designed for speed and scalability. This allows SH POWER to efficiently manage large-volume projects or fast-turnaround orders without compromising quality.

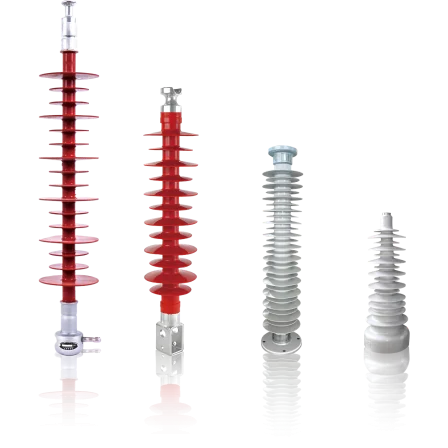

Absolutely. SH POWER can tailor products for voltage class, environmental conditions, or project-specific requirements. We work closely with clients to deliver customized transformers, hardware fittings, composite insulators, and switchgear that meet precise technical specifications.

SH POWER provides integrated energy infrastructure services backed by a complete in-house manufacturing system. Our capacity covers low pressure die casting, high pressure die casting, aluminum forging, CNC machining centers, and a full power transformer production line, enabling stable, end-to-end production for global energy infrastructure projects.

Yes. SH POWER is structured to support long-term and multi-region deployment. With standardized workflows, scalable production lines, and vertically integrated processes, we provide stable output for utilities, EPC contractors, and equipment suppliers worldwide. As a trusted energy infrastructure partner, SH POWER ensures consistent manufacturing capacity and long-term supply security for global projects.