SH Power offers full life-cycle support for its transformers,covering solution design, model optimization, and on-site commissioning—all handled by our experienced technical team. We provide tailor-made solutions for various applications to ensure efficient operation and maximize energy savings.

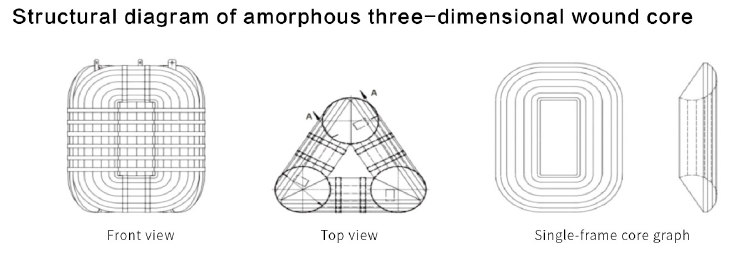

Encouraged by the national energy conservation and environmental protection policy, amorphous alloy transformers are broadly applied in the power distribution field. Continuing progress in technology has stimulated the fast development of amorphous alloy three-dimensional wound core transformers as new popular products in the power distribution field. Instead of the flat wound core structure in a conventional amorphous alloy transformer, our company employs the three-dimensional wound core structure in combination with low-loss alloy belts to produce amorphous alloy three-dimensional wound core transformers. Therefore, our products are characterized by high-strength core, strong resistance to short circuit, even temperature rise, low noise, three-phase balance, low no-load current, reduced consumption of material and energy and low flux leakage. The amorphous three-dimensional wound core is an assembly of three single identical frames. After assembly, the three-dimensional structure of equilateral triangles is stable with high mechanical strength, consistent three-phase stress, improved resistance against short circuit.Under the same conditions, amorphous three-dimensional wound core transformers feature lower noise, greater resistance to local short circuit, smaller size and weight, and lower production and operating costs. Therefore, amorphous alloy three-dimensional wound core transformers have a broad prospect of application and significant social and economic value. Technical | |||||||

| Transformer types: | Amorphous three-dimensional rolled iron core transformers | ||||||

| Transformer capacity(kVA): | 500 | 630 | 1000 | 1250 | 1600 | 2000 | 2500 |

| Primary Voltage(kV): | 6, 6.3, 6.6, 10, 10.5, 11, 11.5 | ||||||

| Secondary Voltage(kV): | 0.315, 0.34, 0.36, 0.4, 0.50, 0.69, 0.8 | ||||||

High-voltage Tapping Range(%): | ±5,±2×2.5 | ||||||

| Connection Symbol | Dyn11, Yyn0, Yd | ||||||

| No-load Loss(kW): | 0.19 | 0.25 | 0.36 | 0.425 | 0.5 | 0.55 | 0.67 |

| Load Loss(kW 75°C): | 4.38 | 5.02 | 8.34 | 9.72 | 11.75 | 14.0 | 16.23 |

| No-load Current(%): | 0.2 | 0.15 | |||||

| Short-circuit Impedance(%): | 4.5-5 | ||||||

Product functions

Applications

| Model | Energy Efficiency Standard | Capacity Range | Voltage Level | Applications |

| Amorphous alloy three-dimensional wound core transformer | NX1/NX2 | 100kVA~630kVA | 10kV | Power distribution market |

| Amorphous alloy three-dimensional wound core transformer | NX1/NX2 | 2000kVA~3450kVA | 33kV,35kV,37kV,38.5kV | Photovoltaic and wind power markets |

| The amorphous alloy three-dimensional wound core transformer has many advantages, and is much superior to the conventional amorphous transformer in terms of environment-friendliness, material saving and grid-connected operating stability. It is a new development in the transformer market. As a “Champion of the Environment” up to its name, the amorphous alloy three-dimensional wound core transformer is gaining more popularity in the current social environment where the country pursues the carbon peaking and carbon neutrality goals, and advocates a “green, environment-friendly and low-carbon” lifestyle. | ||||

Including oil-immersed, dry-type and packaged substation transformers to cover all voltage levels and application needs.

Built with high-grade grain-oriented silicon steel and premium insulation systems for low no-load and load losses and outstanding energy savings.

Oil-immersed and packaged units offer superior moisture-proof, leak-proof and dielectric performance, guaranteeing long-term stability.

The entire process strictly follows national standards and ISO 9001 quality management system.

Custom designs are available to match specific site conditions and load characteristics.

Robust construction incorporates overload and high-temperature protection functions.

Compliant with RoHS and other environmental regulations—low noise, minimal losses.

Our 110kV and 220kV power transformers are widely used in power plants and transmission substations for efficient voltage transformation.

We provide specialized solutions, including inverter and step-up integrated transformers, for renewable energy projects like solar farms and wind power plants.

Our dry-type and pad-mounted transformers are perfect for industrial facilities, commercial complexes, data centers, and high-rise buildings, providing safe and reliable power distribution.

Our distribution transformers, including pole-mounted and pad-mounted types, are essential for urban and rural power grids, delivering electricity to homes and public facilities.