Data Center

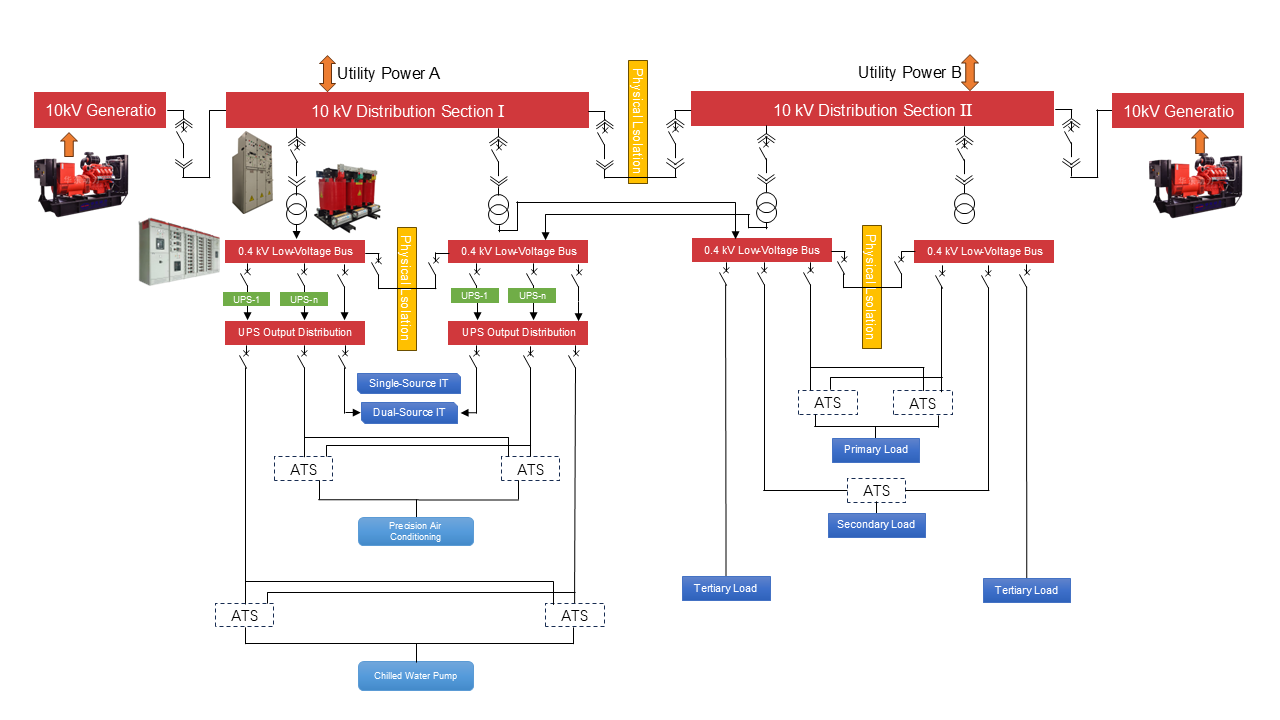

For mission-critical IT loads and continuous operations, we deliver full-stack solutions including dual-power supply, dynamic reactive compensation, intelligent distribution, and cooling optimization. Core products—SCB(H) dry-type transformers, MNS low-voltage switchgear, and GGF reactive compensation systems—meet Tier III+ standards, ensuring 99.999% availability.

Customer Value

- HV switchgear & power transformers: Ensure efficient transmission and stable distribution at 110 kV/220 kV level, minimizing losses and guaranteeing 24×7 uptime.

- MV/LV Electrical Switchgear: IP54+ ingress protection, arc-fault containment, integrated vacuum circuit breakers (VCBs) and protective relays for sub-cycle fault clearing, safeguarding personnel and IT loads.

- Emergency diesel generator sets: Stand-by gensets with NFPA 110 Level 1 compliance, 10-second start-to-load capability to prevent data loss and service interruption.

- Ultra-high-efficiency transformers: Amorphous-core or laser-scribed grain-oriented (Hi-B) designs cut no-load losses by ≥20 %.

- Low-loss switchgear: Low-consumption vacuum interrupters and contactors reduce total losses by ≥15 %.

- Intelligent EMS/SCADA: Real-time asset monitoring and AI-based load optimization continuously shave kWh and peak demand.

- Tailor-made designs: High-capacity, high-density switchboards and transformers up to 4 MVA in a single skid.

- Modular architecture: Prefabricated electrical houses (E-houses) and skid-mounted gear enable hot-swappable expansion with minimal CAPEX.

- Wide voltage portfolio: From 400 V LV to 220 kV EHV to cover every tier of the data-center power train.

- Smart condition monitoring: Embedded IoT sensors + edge analytics give predictive-fault alerts weeks in advance.

- Remote O&M: IEC 61850-compliant secure gateways allow remote switching, parameter tuning, and firmware updates.

- Digital-twin optimization: Physics-based models fed by live data continuously refine set-points for maximum efficiency.

- Installation & commissioning: Certified technicians complete FAT/SAT and energize systems within 24 h of site readiness.

- Planned maintenance: Reliability-centered maintenance (RCM) programs extend MTBF and preserve warranty.

- 24×7 support: One-hour response SLA, 24-hour MTTR, with global spares hubs to minimize downtime.

- CAPEX: Lean manufacturing and design-for-assembly reduce first cost by ~10 % versus comparable OEMs.

- OPEX: Energy-efficient components cut annual electricity spend by ~20 %.

- Maintenance: Modular, drawer-type withdrawable units cut service labor and spare-part inventory costs by ~30 %.

Customer Story

Epoch Data Center 275kV Gls Substationin Malaysia

Project Background & Client Requirements Data Center Market Trends: Malaysia is actively developing...

Malaysia Princeton Data Center Downstream 33kV GIS Substation Equipment Supply Project

Project Background & Client Requirements Data Center’s Critical Power Supply Requirements:...

Malaysia PDG Data Center Substation Project

Project Background & Challenges Mission-Critical Objective: Construct a 220/35kV primary substation...