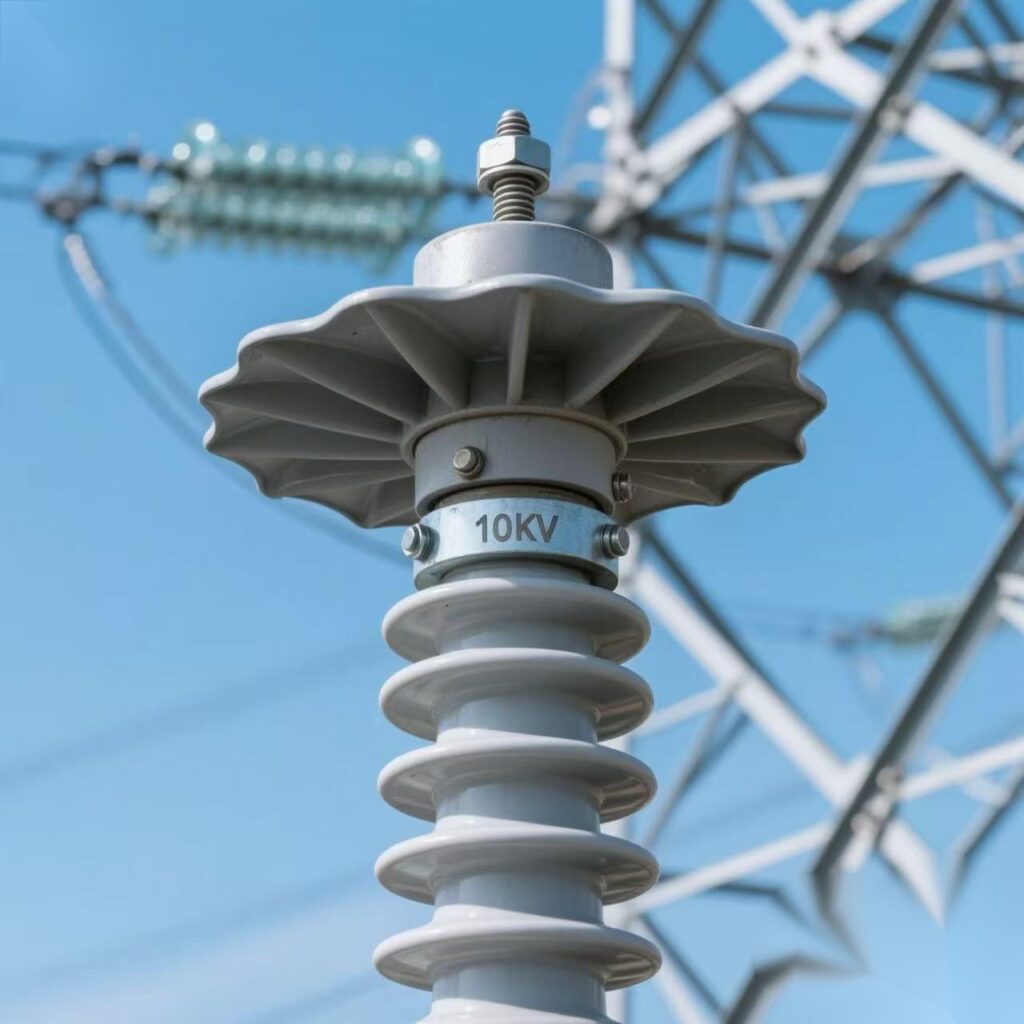

Hello! As a supplier of 10kV composite post insulators, I’m excited to detail the extensive customization possibilities for these critical components. Tailoring them ensures optimal performance in diverse electrical applications.

1. Physical Dimensions

Length/Height: Adjustable to fit spatial constraints (e.g., compact substations) or extended clearances between components.

Diameter: Enhanced thickness boosts mechanical strength for high-wind zones or impact-prone areas.

Bending Load Capacity: Custom core reinforcement supports specific mechanical loads (e.g., seismic regions).

2. Shed Design & Configuration

Shed Number/Spacing: Increased sheds extend creepage distance, critical for pollution-heavy or humid environments.

Shed Profile:

Deep/Undulated Sheds: Rapid water shedding in rainy climates.

Aerodynamic Shapes: Reduces ice/snow accumulation in cold regions.

Surface Geometry: Optimized for self-cleaning to minimize contamination buildup.

3. Material Selection

Core: Fiberglass-reinforced polymer (FRP) grades adjustable for tensile strength (e.g., corrosive/UV-intensive sites).

Housing: Silicone rubber formulations with:

Enhanced Hydrophobicity: Repels moisture in coastal/rainy areas.

High Tracking Resistance: Prevents arcing damage in polluted settings.

UV Stabilizers: Prolongs lifespan in high-sunlight regions.

Additives: Flame retardants or anti-aging agents for extreme conditions.

4. Electrical Performance

Flashover Voltage: Elevated via extended creepage distance or optimized shed design.

Power Frequency Withstand Voltage: Tailored to handle grid surges (e.g., lightning-prone zones).

Leakage Current Control: Modified material conductivity reduces energy loss.

5. End Fittings

Connection Types: Threaded, flanged, or grooved bases to match mounting hardware.

Material: Corrosion-resistant alloys (stainless steel/hot-dip galvanized) for coastal/industrial sites.

Interface Design: Integrated stress-relief features to prevent cracking at attachment points.

6. Color & Marking

Color Coding: High-visibility hues (e.g., orange for hazard zones) or brand-aligned shades.

Laser Etching: Permanent voltage ratings, serial numbers, logos, or QR codes for traceability.

7. Other Custom Solutions

We also tailor:

69kV Line Post Insulators: For higher voltage distribution.

220kV Composite Post Insulators: Transmission-level reliability.

Integrated Arresters: Lightning protection for 10kV lines.

8. Why Customize?

Every project has unique environmental and operational demands. Examples:

Desert Installations: UV-stabilized housing + extended creepage distance.

Coastal Grids: Corrosion-proof end fittings + hydrophobic silicone.

High-Pollution Zones: Multi-shed design + tracking-resistant material.

Let’s Collaborate!

Share your project specifics—voltage needs, environmental challenges, or mechanical loads—and we’ll engineer precision-fit insulators. Contact us to discuss 10kV solutions or explore our 69kV, 220kV, and arrester-integrated options.

References

- IEEE Std 957-2018 (Insulator Design Guidelines)

- AC Flashover Performance of Iced 10kV Insulators in High Altitude Areas

- Anti-Thunder Composite Insulator Ice Accretion Study

- Composite Insulator Pollution Flashover Mechanisms