Table of Contents

ToggleI. Core Definition: Oil-Free Insulation Technology Innovation

Dry-Type Transformer is a power transformer that does not rely on liquid insulation medium. Its windings and core are directly exposed to air or encapsulated with solid insulating materials. Through high-grade insulation materials and special cooling technology, it achieves the same power conversion function as oil-immersed transformers, while offering higher safety and environmental friendliness.

Using natural air cooling or forced air cooling, it avoids the risks of oil leakage and fire associated with oil-immersed transformers, making it particularly suitable for safety-critical locations.

II. Structural Features: Triple Protection Insulation System

II. Structural Features: Triple Protection Insulation System

Winding Insulation:

Epoxy resin casting: Vacuum cast molding, insulation class F (155℃) or H (180℃)

Impregnation treatment: Multiple impregnations with high-temperature insulating varnish

Core Structure:

High-quality cold-rolled silicon steel sheets, 45° full mitered joints

Stepped lap construction, reducing no-load loss by 20-30%

Cooling System:

Natural air cooling (AN)

Forced air cooling (AF), capacity increase 40-50%

III. Performance Advantages: The Smart Choice for Safety and Environment

| Aspect | Oil-Immersed Transformer | Dry-Type Transformer |

|---|---|---|

| Insulation medium | Mineral oil | Air/solid materials |

| Fire performance | Class B2 (combustible) | Class F1 (flame retardant) |

| Environmental | Waste oil disposal | Recyclable materials |

| Installation | Explosion-proof room | Direct installation |

| Maintenance cost | Regular oil testing | Maintenance-free |

Additional advantages:

Strong overload capacity: Short-term overload up to 150%

Easy installation: No oil pit or fire wall needed

Easy smart integration: Temperature monitoring systems

IV. Applications: Safety-First Critical Locations

IV. Applications: Safety-First Critical Locations

Indoor distribution:

Commercial centers: Beijing CBD uses SCB13 dry-type transformers

Data centers: Alibaba Zhangbei data center with thousands of dry-type transformers

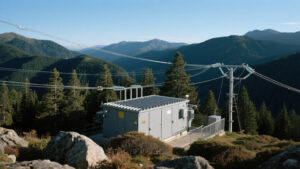

Special environments:

Subway tunnels: Guangzhou Metro Line 3 uses dry-type transformers throughout

Offshore platforms: Bohai oil field platforms with anti-salt spray type

Sensitive locations:

Hospital operating rooms: Ensuring no oil contamination risk

Chemical plants: Explosion-proof and corrosion-resistant requirements

V. Technical Parameters: Precision Engineered Performance

Electrical performance:

Capacity range: 30kVA-20MVA

Voltage level: 10kV-35kV

No-load loss: 20-30% lower than national standard

Load loss: 15-25% reduction through optimized design

Insulation performance:

Insulation class: F or H

Temperature rise limit: 100K (F), 125K (H)

Protection level: IP00-IP23

Environmental performance:

Noise level: ≤55dB (at 1m)

Recycling rate: ≥95%

Hazardous substances: RoHS compliant

VI. Selection Guide: Choosing the Right Model

VI. Selection Guide: Choosing the Right Model

By usage environment:

Ordinary indoor: IP20 protection

Humid environments: IP23 protection

Corrosive environments: Special coating treatment

By load characteristics:

Stable load: Standard models

Impact load: Enhanced insulation models

Nonlinear load: K-factor transformers

By efficiency requirements:

Level 1 efficiency: SCB13 and above

Super level 1 efficiency: SCB14, SCB18

Amorphous alloy: 70% lower no-load loss

II. Structural Features: Triple Protection Insulation System

II. Structural Features: Triple Protection Insulation System IV. Applications: Safety-First Critical Locations

IV. Applications: Safety-First Critical Locations VI. Selection Guide: Choosing the Right Model

VI. Selection Guide: Choosing the Right Model