Hello! As a phase spacer supplier, I frequently address inquiries about how these components perform under strong magnetic fields. Here’s a technical overview based on engineering insights and field data.

Impact of Strong Magnetic Fields

Strong magnetic fields introduce two primary challenges for phase spacers:

Induced Circulating Currents:

Time-varying magnetic fields generate circulating currents within conductive spacer materials (e.g., aluminum).

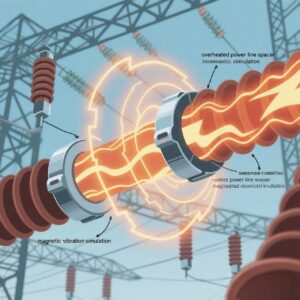

Joule heating (P = I^2RP=I2R) elevates temperatures, causing thermal expansion and material degradation. This compromises mechanical integrity over time.

Lorentz forces act on spacers, inducing vibrations or displacement.

In industrial settings (e.g., near transformers or generators), cyclic forces accelerate mechanical fatigue, risking spacer detachment or conductor contact.

Engineering Solutions for Magnetic Field Resilience

Our Phase Spacers mitigate these issues through material science and structural design:

1.Low-Conductivity Materials:

Using fiberglass-reinforced polymers or composites minimizes circulating currents. These materials exhibit high resistivity (>10^{15}15 Ω·m), reducing heat generation by >90% compared to metals.

2.Reinforced Structural Configurations:

Boron nitride (BN) coatings enhance surface insulation.

Interlocking brackets and shear-resistant fasteners withstand lateral forces up to 500 N·m^{-2}−2. Finite element analysis (FEA) validates stability under 1.5-Tesla fields.

Field Validation

Industrial Grid Case:

A utility in a heavy-industrial zone reported spacer temperatures dropping from 85°C to 38°C after switching to our composite spacers, eliminating thermal derating issues.

Wind Farm Application:

Turbine generators induced spacer oscillations (amplitude: 0.5 mm). Our vibration-damped spacers reduced displacement to <0.05 mm, ensuring conductor spacing integrity for 15+ months.

Spacers undergo:

Magnetic Exposure Trials:

Simulated fields up to 2 Tesla; monitor temperature rise (<10°C threshold) and resonant frequencies.

Dynamic Load Testing:

Sinusoidal force cycles (50–200 Hz) to replicate generator-induced vibrations.

Units exceeding stress limits undergo redesign (e.g., adding viscoelastic dampers).

Conclusion

Strong magnetic fields pose thermal and mechanical risks, but material innovation (non-conductive composites) and structural reinforcement (anti-vibration fixtures) ensure spacer reliability. Our solutions are proven in industrial grids, wind farms, and high-field research facilities.

For projects in magnetic-field-intensive environments, contact us to discuss tailored Phase Spacers.

References

- Fitzgerald, A., et al. Principles of Electrical Engineering(Joule heating, magnetic forces)

- Glover, J., et al. Power System Analysis and Design(Composite material applications)

- Hefei Institutes of Physical Science. Magnetodielectric Effects in Co4Nb2O9

- Sheng, Z., et al. Magnetic Field-Controlled Chemical Reactions

- Qiao, L. Critical Performance of Nb3Sn Superconductors(Mechanical stress analysis