Hello! As a composite cross-arm insulator supplier, I’m often asked whether these units perform in deserts. The answer is a resounding yes—here’s why:

Extreme Temperature Adaptability

Deserts experience drastic daily swings (40–50°C daytime highs, 10–20°C nighttime lows). Composite cross-arm insulators excel here:

Their fiberglass cores maintain structural integrity from -40°C to 70°C, far exceeding typical desert ranges.

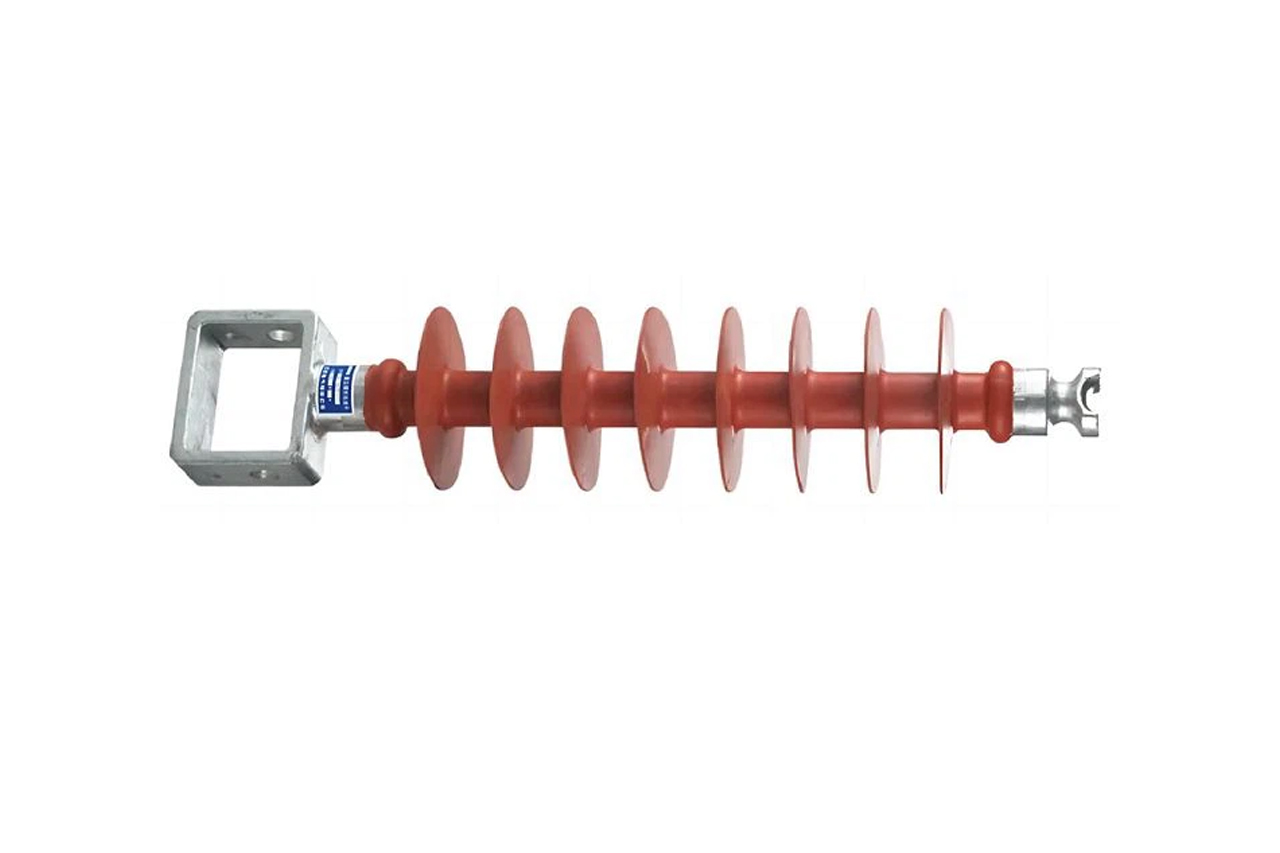

Silicone rubber housings flex without cracking during rapid thermal cycles. Our 35kV models undergo rigorous validation for these conditions.

1.Sand and Dust Resistance

Abrasion from sand particles is mitigated by:

- Robust silicone rubber surfacesthat resist erosion while preserving electrical properties.

- Smooth, non-stick exteriorsthat shed dust accumulation, reducing contamination risks.

2.Electrical Reliability

Desert dust buildup threatens insulation, but composite designs counter this:

Inherent hydrophobicity causes water to bead, preventing conductive layers from forming.

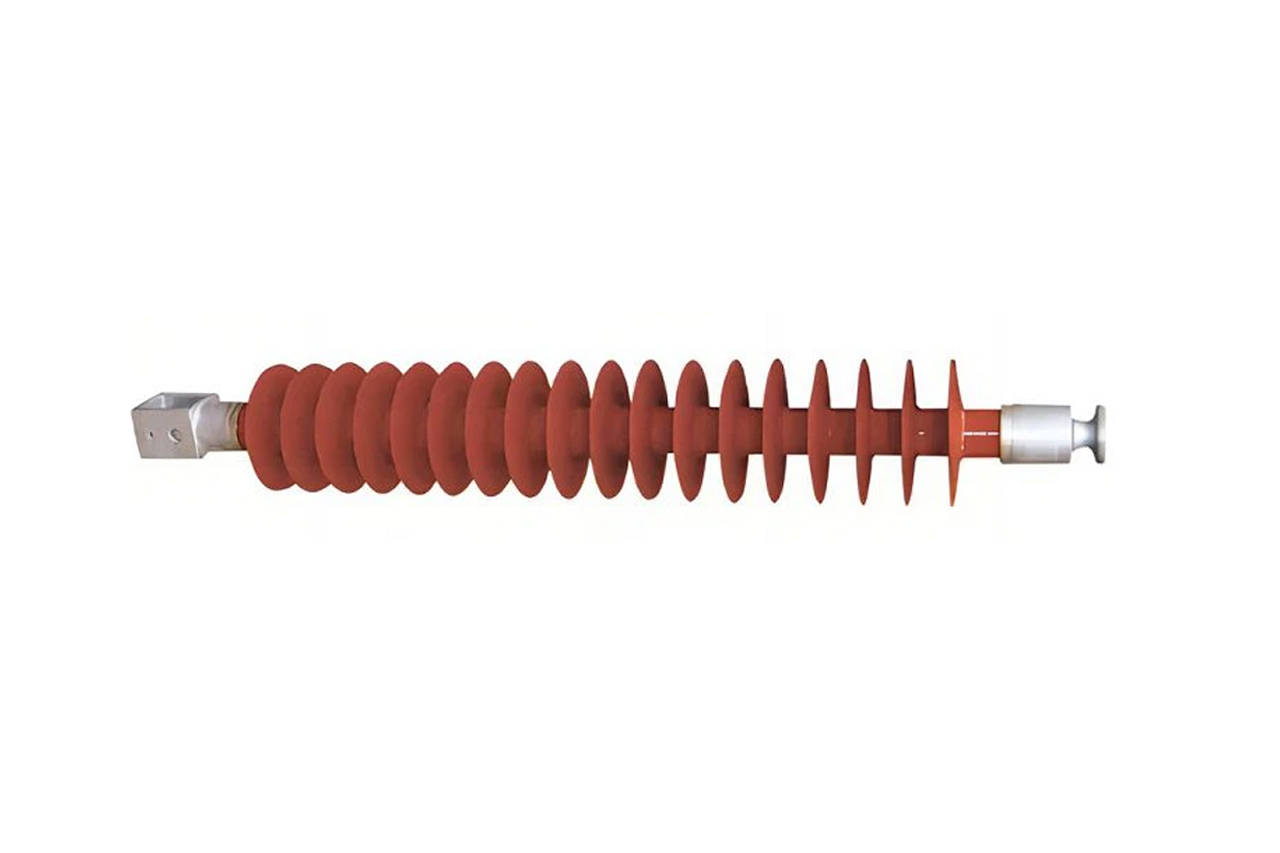

Superior pollution flashover resistance—achieving 2–2.5× higher withstand voltage than porcelain equivalents. Our 110kV insulators feature optimized shed shapes for desert duty.

3.Sandstorm Resilience

High winds and debris pose minimal risk due to:

Exceptional mechanical strength: Fiberglass cores offer 2× the bending strength of steel and 8–10× that of ceramic.

Lightweight construction: At just 1/6–1/9 the weight of porcelain units, they impose less stress on supports and resist impact damage.

Installation and Maintenance Advantages

Easy deployment: Lightweight design simplifies transport and installation in remote deserts.

Near-zero maintenance: No cleaning or frequent replacements needed. Real-world projects (e.g., China’s Northwest 750kV lines) show 60% lower lightning trip rates and reduced lifecycle costs versus traditional structures.

Voltage-Specific Solutions

We offer tailored options:

10kV: Integrated lightning protection for distribution networks.

35kV/110kV: Reinforced silicone formulations and crimped fittings for mechanical durability.

Conclusion

Composite cross-arm insulators deliver proven reliability in deserts through temperature resilience, sand erosion resistance, electrical stability, and low maintenance. Successful deployments in projects like Saudi Arabia’s smart grids and China’s Northwest transmission corridors confirm their suitability.

For desert applications (10kV, 35kV, or 110kV), contact us for engineered solutions.

References

[1] FS-10/5 Composite Cross-Arm Technical Specs (Temperature Range, Pollution Resistance)

[2] High-Altitude Insulator Performance Study (750kV Project Data)

[3] UHV Composite Cross-Arm Breakthroughs (Pollution & Weight Optimization)

[4] 10kV Desert Grid Lightning Protection Case Study

[5] Thermal Management Materials in Arid Environments (Extended Applications)